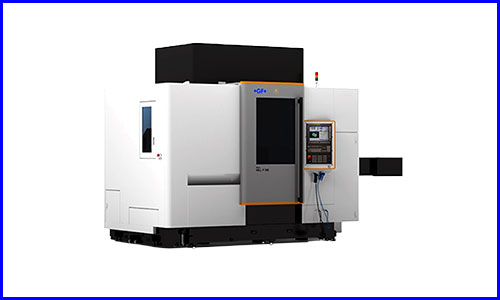

Highly Precise, High Speed Milling Machines

- MIKRON MILL P 900 : 2 Nos

- X, Y, Z Travel 900 x 600 x 450 mm

- Control unit Fanuc 31i- B / iHMI

- Max. load (incl. pallet) 1000 kg

- Rapid traverse X/Y/Z 30 / 30 /30 m/min

- Tool magazine (incl. pallet) D30 / HSK-A63

- Spindle 20,000 (HSK-A63)

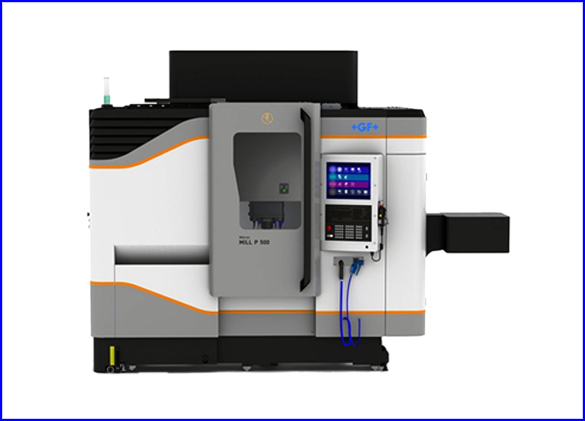

- MIKRON MILL P 500

- X, Y, Z Travel 500 x 600 x 450 mm

- Control unit Fanuc 31i- B / iHMI

- Max. load (incl. pallet) 300 kg

- Rapid traverse X/Y/Z 30 / 30 /30 m/min

- Tool magazine (incl. pallet) D30 / HSK-E40

- Spindle 42 000 (HSK-E40 S6)

High Performance Wire EDM and Sinker-EDM Machines

- AgieCharmilles CUT P 550

- X, Y, Z Travel 550 x 350 x 400 mm

- Travel U, V 550 x 350 mm

- Min. surface roughness RA (steel) 0.08 μm

- Max taper angle / height 45° / 400 mm

- Max. workpiece dimensions 1200 x 700 x 400 mm

- Max. workpiece weight 1500 kg

- Wire diameters 0.07 to 0.33 mm

- AgieCharmilles FORM P 350 : 2 Nos

- X, Y, Z Travel 350 x 250 x 300 mm

- Travel U, V 550 x 350 mm

- Min. surface roughness RA (steel) 0.08 μm

- Distance table/chuck 150 – 450 mm

- Spindle chuck System 3R automatic chuck

- Max. workpiece dimension 790 x 530 x 275 mm

- Max. workpiece weight 500 kg

- Max. electrode weight 50 kg

High Performance EDM Drill Machine

- AgieCharmilles DRILL 20

- Axes travel X/Y/Z: 300 x 200 x 300 mm

- Maximum Drilling Depth: 200 mm

- Electrode Diameter:0.1 to 3 mm

- Max workpiece weight:300 kg

- Table dimension:400 x 300 mm

High Performance Tool Presetting, Balancing and Shrink-fit

Highly Precise CMM and VMM

- CMM: GLOBAL S Chrome

- Measuring range X/Y/Z 900 X 1200 X 800 mm

- Accuracy as per ISO 10360-2 1.3 + L/333 μm (180-220)

- Accuracy as per ISO 10360-2 1.6 + L/250 μm (160-260)

- Probing Error:PFTU 1.3 μm

- Scanning Error THP/t 2/35 sec

- Repeatability range Ro 1.2 μm

- RONt 1.4 μm

- Resolution 0.039 μm

- Max 3D speed 860 mm/sec

- Max 3D acceleration 4300 mm/sec2

- Scanning Speed 1000 points/sec

- Max part weight1300 Kg

- VMM: CNC Optiv Classic 322

- Machine Stroke X/Y/Z 300 X 200 X 200 mm

- Scale Resolution in X,Y,Z Axis 0.05 μm

- Load bearing capacity of the machine 16 Kg

Reverse Engineering and Prototyping

Hexagon Make Blue Light Scanner: Smartscan

Sanco is having world class non-contact precision scanning system from Hexagon with FOV up to 50mm. Machine is capable for precision scanning of all types of components from aerospace, automobile, medical industry.

The smartSCAN systems capture the minutest detail at the highest level of accuracy to detail for any scanning projects, and even under temperature fluctuations operate with consistently stable and reliable performance. With the help of miniaturized projection technique (MPT), smartscan is characterized by very fast data acquisition; even the most complex surface geometries of fragile or deformable parts are captured within seconds at a high level of precision.

The system configuration is easily customized to suit your individual project requirements and the spectrum of the 3D data acquisition ranges from the smallest injection nozzles up to full-size vehicles.

We are experts in quality and dimensional inspection of all types of components and their tooling, eg: components of any material (casting, plastic, sheet metal, wax foam, etc.), their core-cavity, patterns, core boxes, etc.

FORMLABS Make SLA 3D Printer: FORM 3L

Sanco also offers 3D Printing facility with Precision, Repeatability, Quality & Reliability. We have FormLabs make, Form 3L, SLA 3D printing machine installed for our customer’s convenience. With a large build volume of 33.5 × 20 × 30 cm 13.2 x 7.9 × 11.8 in), you can print one large model or many small parts in a single job. This machine can provide XY resolution of 25 microns.

Stereolithography – more commonly referred to as SLA 3D printing – is one of the most popular and widespread techniques in the world of prototyping or additive manufacturing. It works by using a high-powered laser to harden liquid resin that is contained in a reservoir to create the desired 3D shape.

In a nutshell, this process converts photosensitive liquid into 3D solid plastics in a layer-by-layer fashion using a low-power laser and photo polymerization

- SLA is one of the most precise 3D printing techniques on the market.

- Prototypes can be created with extremely high quality, with finely detailed features (thin walls, sharp corners, etc…) and complex geometrical shapes. Layer thicknesses can be made as low as 25 μm, with minimum feature sizes between 50 and 250 μm

- SLA provides the tightest dimensional tolerances of any rapid prototyping or additive manufacturing technology: +/- 0.005″ (0.127 mm) for the first inch, and an additional 0.002″ for each additional inch

- Print surfaces are smooth